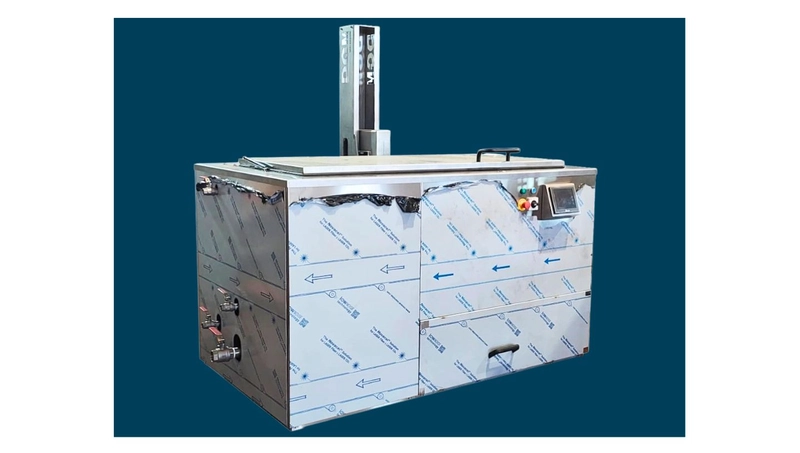

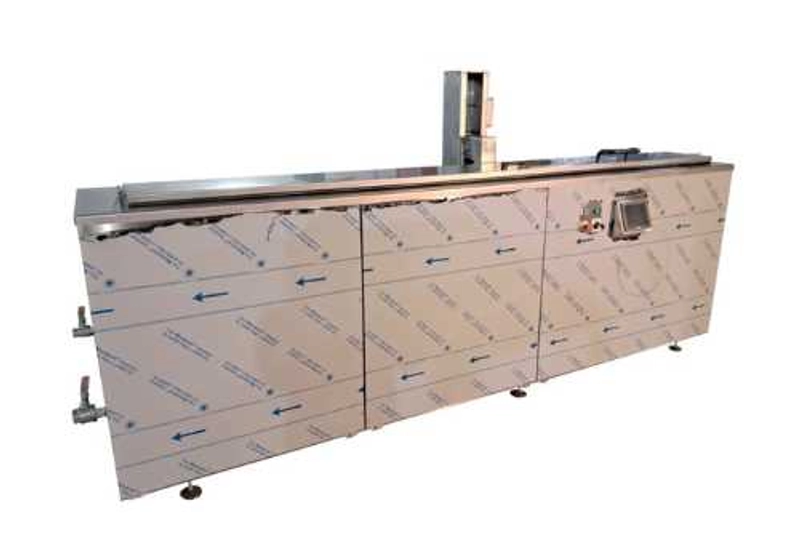

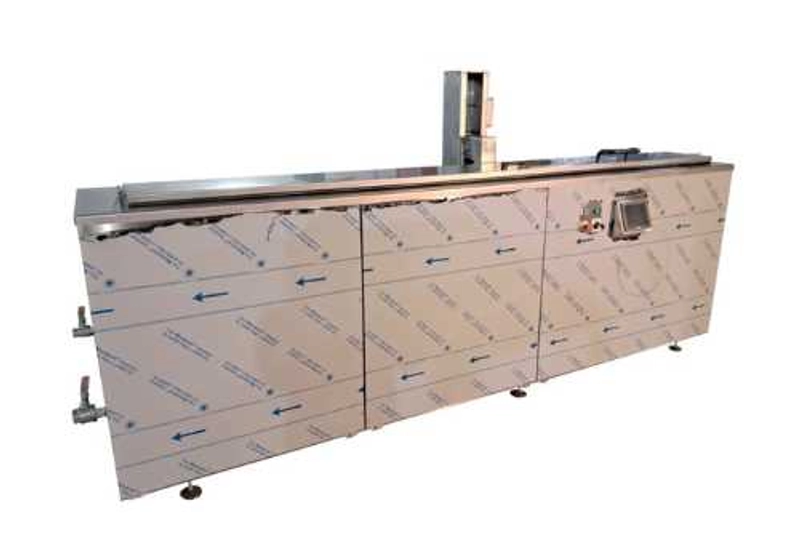

Anilox Roller Cleaning - UCM 500RL

Product price

Price upon request

Payment and shipping information

Anilox Roller Cleaning - UCM 500RL

DCM Ultrasonic

Product details

Anilox Roller Cleaning. Our standard RL (Rotating Loading) series is equipped with a pneumatic lifting platform with a load capacity of up to 500 kg, specifically designed for cleaning Anilox rollers. This lifting system performs three main functions: 1. Facilitates loading and unloading of the parts to be cleaned. 2. Improves cleaning in hard-to-reach areas by generating gentle fluid movement that helps remove loose residue. 3. Evenly distributes the ultrasonic action, avoiding concentration in a single point and thus preventing marking on soft metal parts such as aluminum or zamak. Advanced Ultrasonic Technology. Synchronized Digital Generators. At DCM Ultrasonic, we have developed a synchronized digital generator with an adjustable operating frequency between 24 and 40 kHz. This allows the optimal frequency to be selected for each application. This generator is the result of more than a decade of experience in ultrasonic cleaning, constantly adapting to our customers' needs. High-performance piezoelectric transducers. We use Japanese-made PZT4 piezoelectric transducers, selected after an exhaustive analysis of more than 15 models to ensure maximum performance in combination with our generator. Thanks to this optimization, we achieve high cavitation levels with reduced energy consumption. Thermal and acoustic insulation. Our equipment features an insulation system that minimizes heat loss, maintaining a stable temperature. This avoids unnecessary heating and cooling cycles, optimizing power consumption and reducing operating costs. Robust and functional design. Control system with PLC and HMI. The equipment is equipped with a PLC and a color touchscreen (HMI), offering an intuitive menu for easy operation. It also features an Ethernet communication port, allowing remote monitoring and management of the system. Stainless Steel Construction. The entire structure of the equipment is made of AISI 304L stainless steel, while the ultrasonic emitters are made of AISI 316L stainless steel. The thicknesses of the tank and emitters have been carefully selected to ensure a long service life and excellent system resonance. The result is an efficiency close to 98%, ensuring that virtually all of the electrical energy used to generate ultrasound is mechanically transferred to the tank, minimizing thermal losses.

Specification

Ultrasonic power (W)

4000

Heating power (W)

12000

Tank capacity (liters)

510

External measures LxWxH (mm)

3080 x 790 x 1600

Static maximum load (kg)

500

Port of shipping

Spain

Valencia Port

About the supplier

Visit supplier pageContact supplier

More products from the supplier

Similar product

JANOME MEMORY CRAF...

Computerized Needle Threader Needle Up/Down Setting...

Trading Networks ...

steel rollers, st...

Steel roller, size, material could be tailored, custo...

KN STEEL BALL

Anilox Roller Clea...

Anilox Roller Cleaning. Our standard RL (Rotating Lo...

DCM Ultrasonic

Balloon Squuzer Ma...

Hydro extractor has four main function as follows. Sq...

Noya Mekatronik

Air Relax Dryer Ma...

The main logic of Air Relax Dryer is to provide a qua...

Noya Mekatronik

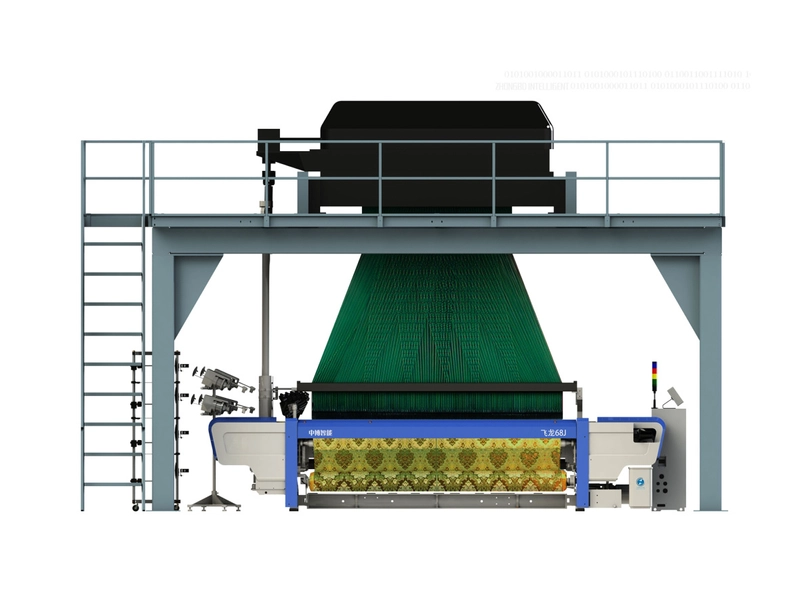

ELECTRONIC JACQUAR...

The DEJ22-5376 is a high-capacity electronic Jacquard...

Dynamic Looms

ZBMaxJ 88 High Spe...

It is suitable for cotton spinning, denim silk, silk,...

Jiangxi Zhongbo I...

Feilong 68J High ...

Suitable for polyester, cotton, silk, viscose, etc., ...

Jiangxi Zhongbo I...

High Speed Plain C...

Industrial Cloth Loom. ZBMax98J type high speed rapi...

Jiangxi Zhongbo I...

Denim Jeans Fabric...

Feilong 68 model high speed rapier loom adopts mature...

Jiangxi Zhongbo I...