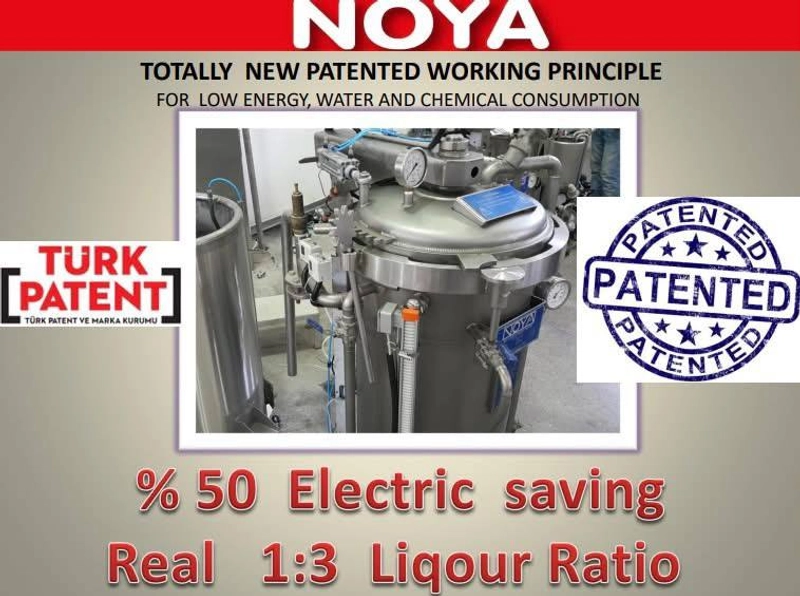

Yarn Dyeing Machine (PATENTED SYSTEM)

Product price

Price upon request

Payment and shipping information

Yarn Dyeing Machine (PATENTED SYSTEM)

Noya Mekatronik

Product details

HT Yarn Dyeing Machine is designed base on the latest technical and technological improvements regard to; liquor flow, liquor circulation and maximum efficiency. Machine can be used for the processing of many different kinds of materials with using different suitable carrier such as bobbins packages, muffs, beams, loose material, tops etc.

Specification

TECHNICAL ADVANTAGES Perfect dyeing results without having unlevelled dyeing effect for max. 2 kg bobbins in weight. Inside/outside and outside/inside two way flow without changing the direction of the snail pump motor. Short and fast heating times by efficient heat exchanger Dyeing capacity of min 50% and max. 100% with air pad system Perfect dyeing possibility on every pressure with differential pressure transmitter Repeatability by automation system Short dyeing times with the help of 100% reserve tank Liquor ratio in between 1:5 - 1:8 Single or double material carrier Heat exchanger in the circulation pipe line Rapid lid opening, closing, locking system Heavy duty stainless steel centrifugal pump with mechanical seal. DRYING PROCESS CONSISTS OF 3 SEQUENCES; HYDROEXTRACTION: replaces centrifugal operation and is done directly after loading of wet yarn carrier coming from dyeing machine. DRYING: Drying process starts automatically alter hydroextraction. The air is blown by the blower through heat exchanger for heating, heated at preset temperature according to yarn type and colour shade, flows at high speed through the yarn 1/0 direction, thereby transferring heat to the yarn and saturating with evaporated water. Duration of drying phase is preset on the base of air temperature at inlet and outlet of yarn packages 3 - YARN CONDITIONING: After the drying phase, air is circulated O/l direction in order to equalize residual humidity in yarn packages and reduce the temperature of the yarn. ADVANTAGES: No need of centrifuge hydro extractor. Loading and unloading is the waste time and also yarn packages may be damaged during loading /unloading. Process time is 50% to 70% shorter due to closed loop. Labour is dramatically reduced in the whole drying process.

Port of shipping

Turkey

Izmir Port

About the supplier

Visit supplier pageContact supplier

More products from the supplier

Similar product

JANOME MEMORY CRAF...

Computerized Needle Threader Needle Up/Down Setting...

Trading Networks ...

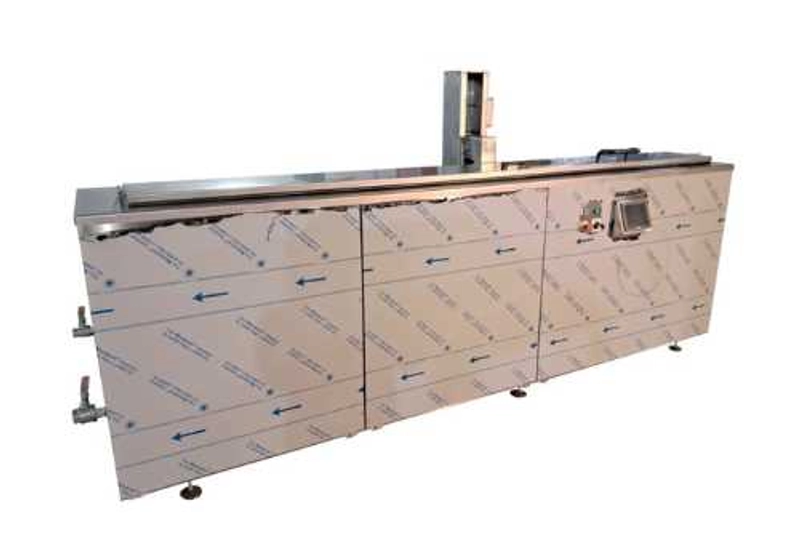

Anilox Roller Clea...

Anilox Roller Cleaning. Our standard RL (Rotating Lo...

DCM Ultrasonic

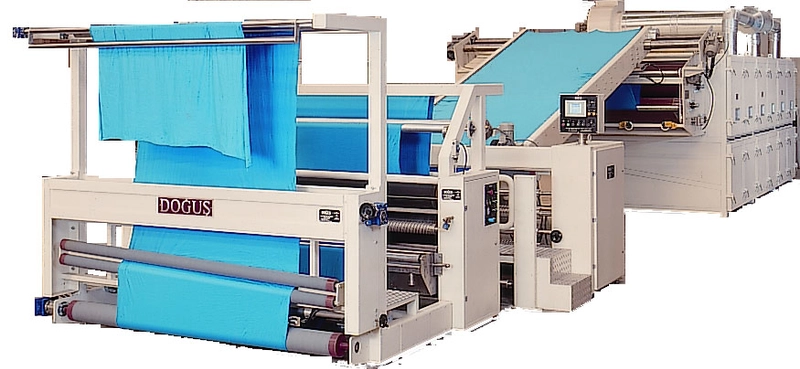

HT Fabric Dyeing M...

PATENTED DYNAMIC LEVEL SYSTEM As different from all k...

Noya Mekatronik

ZBMaxJ 88 High Spe...

It is suitable for cotton spinning, denim silk, silk,...

Jiangxi Zhongbo I...

ZBMax98J type high...

It is suitable for cotton spinning, denim silk, silk,...

Jiangxi Zhongbo I...

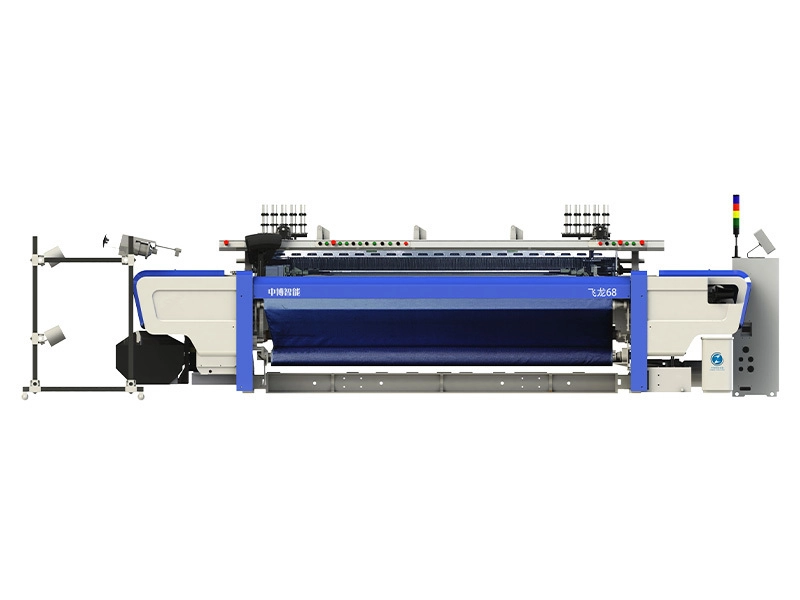

Feilong Model 68 H...

Suitable for weaving cotton, hemp, blended, chemical ...

Jiangxi Zhongbo I...

Denim Jeans Fabric...

Feilong 68 model high speed rapier loom adopts mature...

Jiangxi Zhongbo I...

High Speed Rapier ...

ZBMAX98J High Speed Jacquard Loom: A Versatile Choice...

Jiangxi Zhongbo I...

ZBMAX98J Coffee Be...

Stable operation, convenient maintenance, low noise, ...

Jiangxi Zhongbo I...

Metal Industrial F...

Stable operation, convenient maintenance, low noise, ...

Jiangxi Zhongbo I...