Sales manager

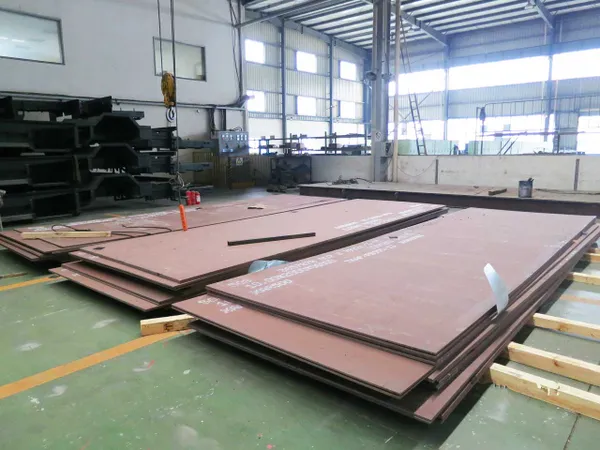

Abrasion Resistant (AR) Steel Plate

Product price

Price upon request

Payment and shipping information

Abrasion Resistant (AR) Steel Plate

SHANDONG JINBAICHENG METAL MATERIALS LIMITED

Product details

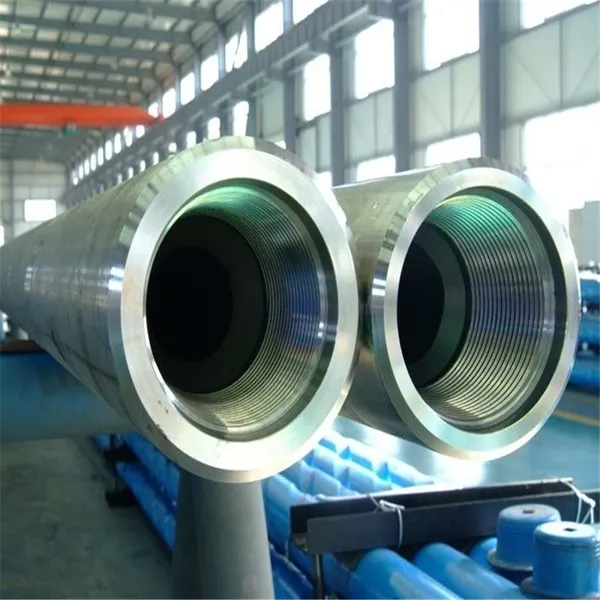

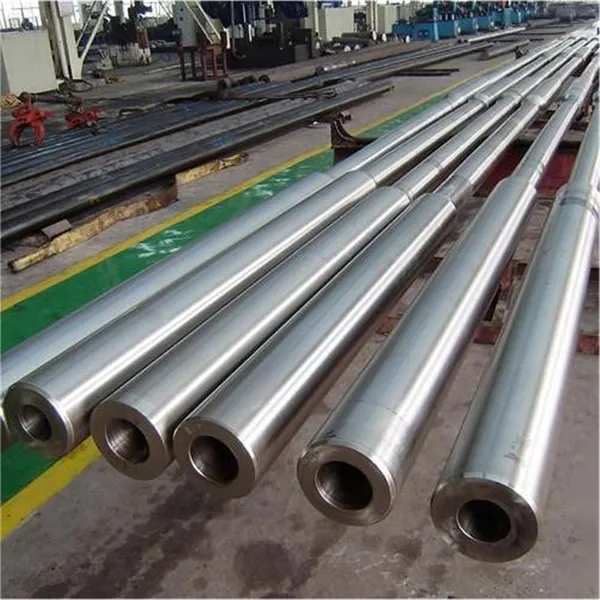

Standard: ASTM, JIS, GB, EN, etc Grade: AR360 AR400 AR450 AR500, AR600, etc Thickness: 5mm-800mm Width: 1000mm, 2500mm, or as the request Length: 3000mm, 6000mm, or as the request Surface: Plain, checkered, coated, etc. Bundle Weight: 5mt or as requested Approval By Third Party: ABS, DNV, SGS, CCS, LR, RINA, KR, TUV, CE Delivery Time: 10-15 days What is Abrasion Resistant Steel Plates Abrasion-resistant (AR) steel plate is a high-carbon alloy steel plate. This means that AR is harder due to the addition of carbon, and formable and weather resistant due to added alloys. Carbon added during the formation of the steel plate substantially increases toughness and hardness but reduces strength. Therefore, AR plate is used in applications where abrasions and wear and tear are the main causes of failure, such as industrial manufacturing, mining, construction, and material handling. AR plate is not ideal for structural construction uses like support beams in bridges or buildings. Abrasion Resistant Steel Jinbaicheng MetalCan Supply AR200 AR200 steel is an abrasion-resistant medium steel plate. It is medium-carbon manganese steel with a moderate hardness of 212-255 Brinell Hardness. AR200 can be machined, punched, drilled, and formed and is known to be an inexpensive abrasion-resistant material. Typical applications are material chutes, material moving parts, and truck liners. AR235 AR235 carbon steel plate has a nominal hardness of 235 Brinell Hardness. This steel plate is not meant for structural applications, but it is intended for moderate wear applications. Some typical applications are bulk material handling chute liners, skirt board liners, cement mixer drums and fins, and screw conveyors. AR400 AR400F AR400 steel is designed for abrasion and wear-resistant applications. The high-carbon alloy steel grades are determined on the hardness of the steel. The AR400 steel plate is often used in applications where abrasion-resistant, formability, and weldability are required. Some typical industries are mining, material handling equipment, and aggregate. AR450 AR450F AR450 steel plate is an alloy composed of different elements, including carbon and boron. It offers more hardness than the AR400 steel plate while maintaining good formability, ductility, and impact resistance. Therefore, it is commonly used in moderate to heavy-wear applications like bucket components, construction equipment, and dump body trucks. AR500 AR500F AR500 steel plate is a high-carbon steel alloy and has a surface hardness of 477-534 Brinell Hardness. This increase in strength and abrasion resistance provides a greater impact and sliding resistance but will make the steel less malleable. AR500 can resist wear and abrasion, both improving equipment’s longevity and increasing production time. Typical industries are mining, material handling, aggregate, dump trucks, material transfer chutes, storage bins, hoppers, and buckets. AR600 AR600 steel plate is the most durable abrasion-resistant plate that Jindalai Steel offers. Due to its good abrasion resistance, it is ideal for excessive wear applications. The AR600 surface hardness is 570-640 Brinell Hardness and is often used in mining, aggregate removal, bucket, and high wear applications. AR steel is used to help resist material wear and tear including: Conveyors Buckets Dump liners Construction attachments, such as those used on bulldozers and excavators Grates Chutes Hoppers TEL/WHATSAPP: +8617701029715 EMAIL: [email protected] Website: www.sdjbcmetal.com

About the supplier

Visit supplier pageContact supplier

More products from the supplier

Similar product

Hardox 600 Steel S...

Material: Hardox 400, Hardox 450, Hardox 500, Hardox ...

SHANDONG JINBAICH...

S355J2W Corten Pla...

S355J2W+N is a medium tensile, low-carbon manganese w...

SHANDONG JINBAICH...

Abrasion resistant...

Standard: ASTM, JIS, GB, EN, etc Grade: AR360 AR400 ...

SHANDONG JINBAICH...

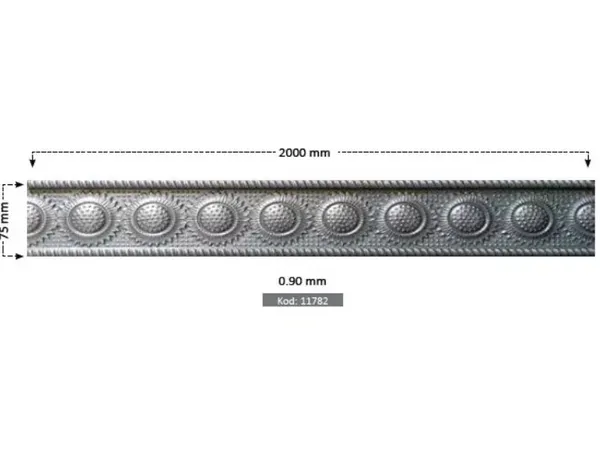

Decorative wrought...

Enhance your property's entrance with a decorative wr...

HAMME MAKINE ANON...

Wrought iron raili...

Elevate your staircase or balcony with a wrought iron...

HAMME MAKINE ANON...

durable grey iron ...

The durable grey iron ball is designed for grinding s...

ANH MINH CO.,LTD

high quality grey ...

Discover excellence in engineering with our high-qual...

ANH MINH CO.,LTD

steel product

the main product:hot/cold rolled coil,pickling coil,g...

faith champ trade...

pre-painted steel ...

thickness :0.1-3.0 mm,width :30-1500 mm,length :custo...

faith champ trade...

iron ore 49% Fe

iron Fe 49%. color - Dark reddish. material type - lu...

sangam