Waterproof WPC Decking Production Line

Product price

Price upon request

Payment and shipping information

Waterproof WPC Decking Production Line

Museco Engimach Pvt Ltd

Product details

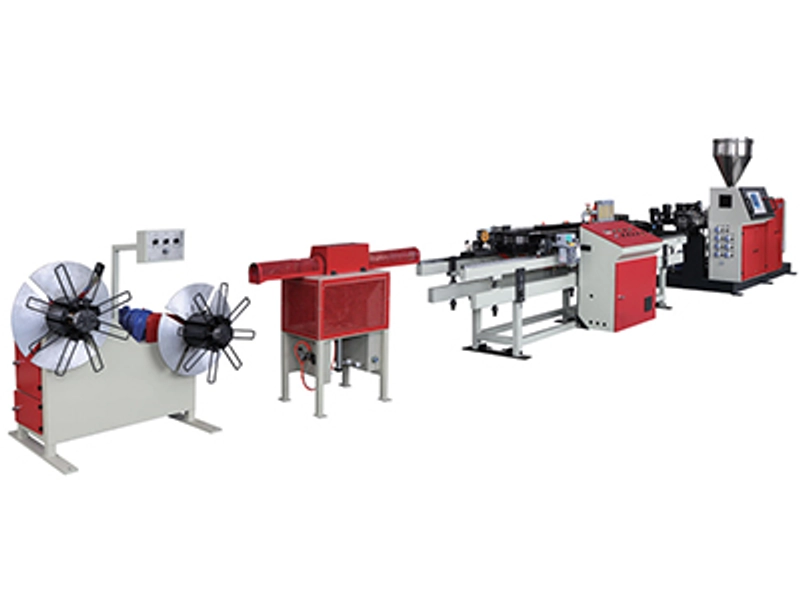

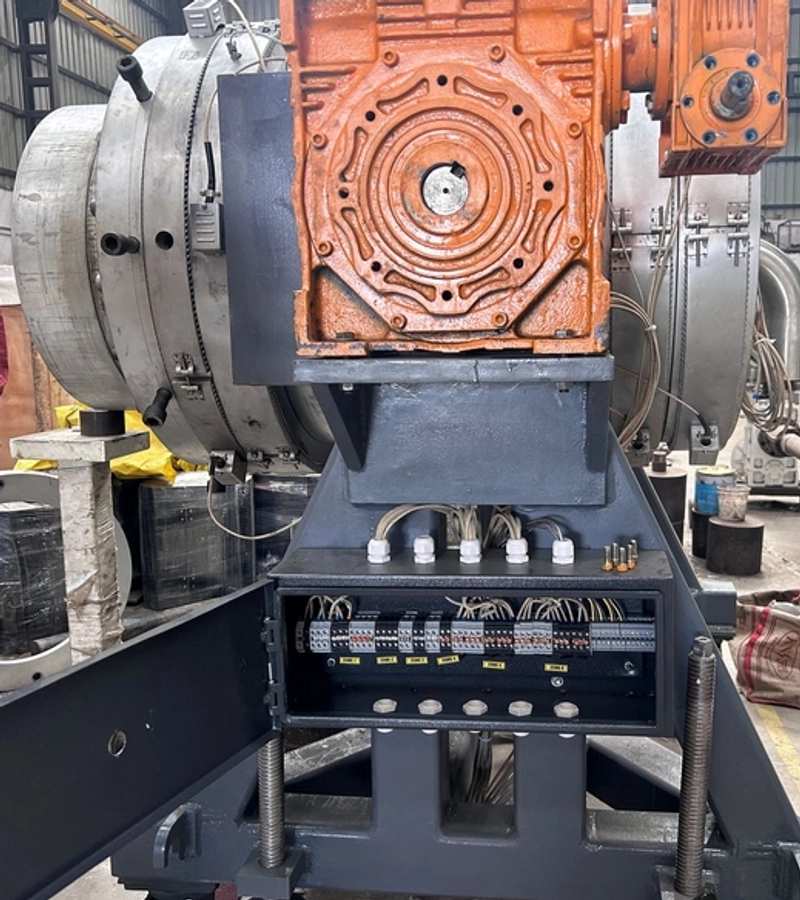

Waterproof WPC decking production line is composed of a material mixer, an auto material loader, an extruder, dies, a vacuum sizing platform, a dragger, a cutting machine, an stacker, etc. By replacing dies, this machine can produce WPC floors,deckings, profiles at customer’s demands. Both host and auxiliary machines use AC variable frequency controlled motor. Both the auxiliary machine’s vacuum pump and traction motor adopt high-quality products and are easy to maintain. PVC WPC floors are mainly applied indoors, such as bathrooms, toilets and bedrooms; and PE WPC floors are mainly used outdoors, such as around the pool, open-air parks, plank and so on. Features of waterproof WPC deckings: Environment-friendly, non-toxic, formaldehyde-free, and recyclable; Vivid wood texture, brilliant color, can deploy a variety of rare and valuable wood colors, and the surface needs no further processing. Fire resistance, effectively reducing household fire hazards; Resistant to moisture and mildew, and resistant to water immersion compared with traditional wood floors, especially applicable to moist environments; Better physical performance than logs, good dimensional stability, no cracks or warping; no wood knots or cross grains; need no regular maintenance; The color can remain unchanged for a long time; Light in weight, convenient to store, transport and carry; and can be drilled, sawn, nailed, planed or pasted like woods. Technical parameters for Waterproof WPC decking production line. Raw material PVC wood or PE wood pellets PVC wood or PE wood pellets. Extruder model SJSZ 51/105 SJSZ65/132. Drive motor power 22KW 37KW. Extrusion capacity 100-130kg/h 200-220kg/h.

Specification

output

kg/hr

Embossing

lazer/hot

Port of shipping

India

Ahmedabad Port, Bhavnagar Port, Bhusawal Port, Bombay Port, Kolkata Port, Calicut Port, Chennai Port, Cochin Port, Dabhol Port, Dahej Port, Dholera Port, Dighi Port, Ennore Port, Goa Port, Gopalpur Port, Haldia Port, Hazira Port, Hyderabad Port, Jafarabad Port, Jakhau Port, Jawaharlal Nehru Port, Kakinada Port, Kandla Port, Kanpur Port, Kanyakumari Port, Karwar Port, Kattupalli Port, Krishnapatnam Port, Kundapur Port, Ludhiana Port, Madras Port, Magdalla Port, Mahe Port, Malpe Port, Mandvi Port, Mangalore Port, Marmagoa Port, Moradabad Port, Mulgund Port, Mumbai Port, Mundra Port, Nagapattinam Port, Navlakhi Port, Neendakara Port, New Delhi Port, New Mangalore Port, New Tuticorin Port, Nhava Sheva Port, Okha Port, Panaji Port, Paradip Port, Pindhara Port, Pipavav Port, Pondicherry Port, Porbandar Port, Port Blair, Ratnagiri Port, Redi Port, Sikka Port, Tadri Port, Trivandrum Port, Tuticorin Port, Vadinar Terminal Port, Valinokkam Port, Vengurla Port, Veraval Port, Visakhapatnam Port, Vishakhapatnam Port, Dadri, Icd Garhi Harsaru, Tumb, Dadri

About the supplier

Visit supplier pageContact supplier

More products from the supplier

Similar product

Plastic Basket mak...

plastic Baskets any plastic products

DM GOLD

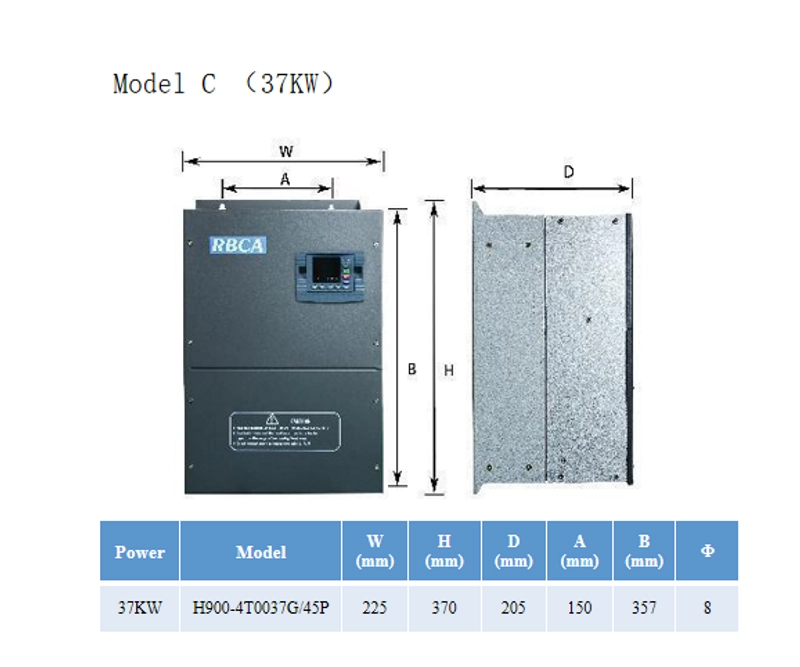

H900 37kw series h...

H900 series high performance current vector inverter....

JIANGSU ROBIN KAN...

H900 45-110KW ser...

H900 series high-performance current vector inverter....

JIANGSU ROBIN KAN...

Cylindrical Drippe...

Thick Wall Dedicated Automatic Winding Device. Automa...

Tianjin Huaxu She...

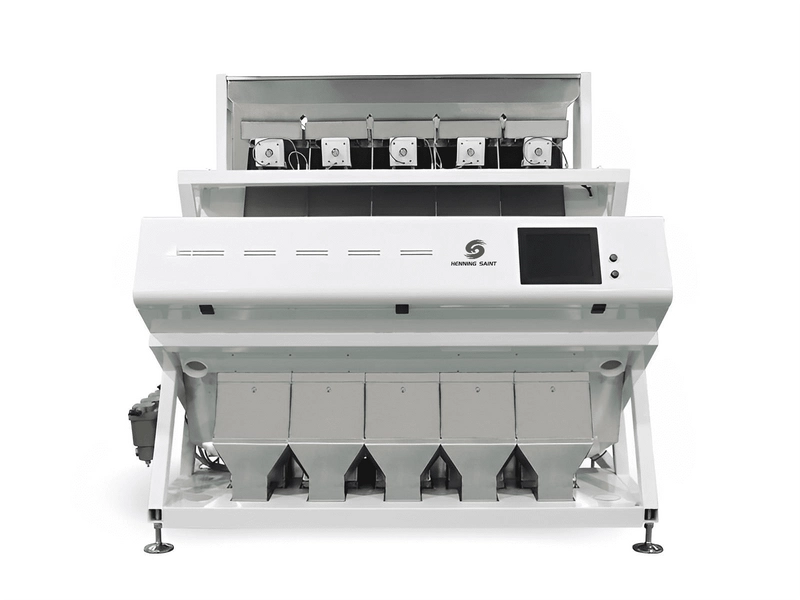

Henning Saint Plas...

The Henning Saint Plastic Color Sorter is a cutting-e...

Anhui Henning Sai...

Wide Web 3D Lens E...

WIDE WEB 3D LENS EMBOSSING MACHINE (MODEL NO. BHI-WW3...

Bajaj Holographic...

Lab Mini Film Extr...

Extrusion blown film is a process in which the plasti...

Dongguan Ju Shang...

Plastic tablet pre...

The cold and hot double-layer tablet press (flat vulc...

Dongguan Ju Shang...

PVC, UPVC, CPVC.PE...

1. UPVC pipe. Material characteristics. UPVC pipe is ...

SHANGHAI YUHAO EN...

Henning Saint PET ...

Henning Saint specializes in advanced optical sorting...

Anhui Henning Sai...