Canned Motor Pump

Product price

3200 USD per UNIT

Payment and shipping information

Canned Motor Pump

Kenshine Pump Mfg Co. , Ltd

Product details

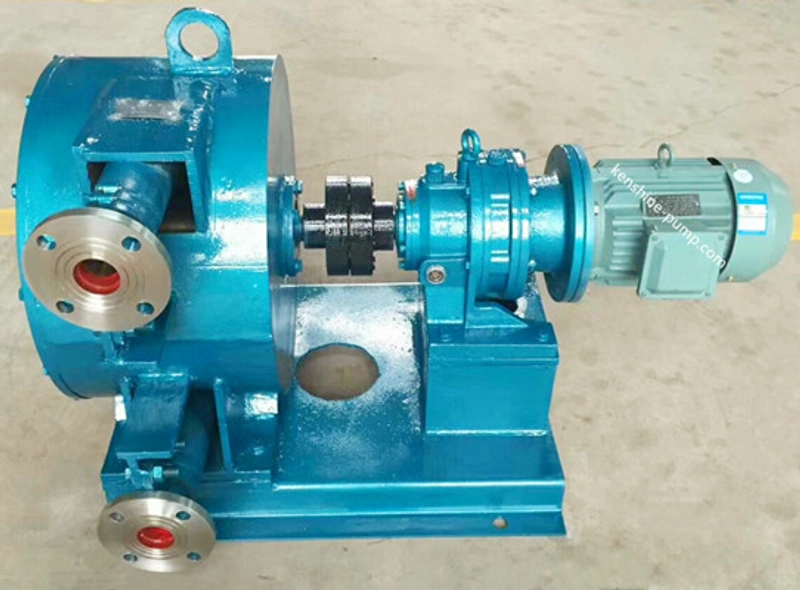

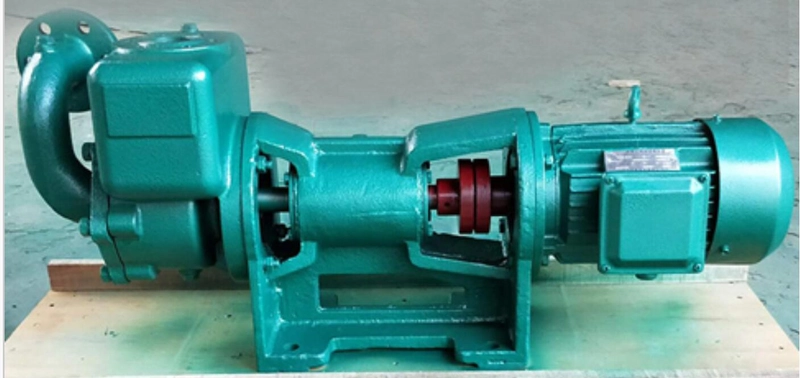

Canned motor pump is composed of a shielded electric motor and a pump. It is a power equipment used for conveying fluids. The equipment is mainly composed of pump body, impeller, stator, rotor, front and rear bearings, thrust disc and other components. The stator and rotor are separated by non-magnetic corrosion-resistant thin-walled sleeves, and the rotor is supported by front and rear bearings immersed in the conveying medium, so no type of dynamic seal is required to prevent the outward leakage of the conveyed medium. Overall, shielded pumps are centrifugal unsealed pumps. Shielded pumps are absolutely leak free, and under negative pressure inside the pump, external gases will not be sucked in, making them particularly suitable for vacuum system operation; At the same time, it is suitable for high pressure, high melting point, and high and low temperature media. Shielded pump has a compact structure, small volume, and light weight; No cooling fan, low noise, wide range of use, reliable operation, can provide a relatively good working environment. A typical shielded pump uses a portion of the conveyed liquid to cool the motor, and the annular gap is very small, so the conveyed liquid must be clean. When transporting multiple liquid mixtures, if they produce precipitation, coking, or gel like substances, using a shielded pump (non mud type) at this time may block the shielding gap, affect the cooling and lubrication of the pump, and lead to burning of graphite bearings and motors. Shielded pumps generally have circulating cooling pipes. When the ambient temperature is below the freezing point of the pumped liquid, anti freezing measures such as accompanying pipes should be taken to ensure easy pump start-up. In addition, when starting the shielded pump, the opening sequence of the outlet valve and the inlet valve should be strictly followed. When stopping the pump, the outlet valve should be closed first. After the pump stops running, the inlet valve should be closed first and then the outlet valve should be closed. In short, by using a shielded pump, there is no leakage at all, effectively avoiding environmental pollution and material loss. As long as the selection is correct and the operating conditions do not change abnormally, there is almost no maintenance workload under normal operation. Shielded pumps are ideal pumps for transporting flammable, explosive, corrosive, and valuable liquids According to the temperature, pressure, viscosity, and presence of particles of the transported liquid, shielded pumps can be divided into the following types. The temperature of the basic conveying medium shall not exceed 120 degree celsius, and the head shall not exceed 150m. Various other types of shielded pumps can be obtained by modifying and improving the basic model. In this type of shielded pump, the direction of liquid flow for bearing lubrication, cooling, and motor cooling is exactly opposite to that of the basic type. Its main feature is that it is not prone to cavitation and is particularly suitable for the transportation of easily vaporized liquids, such as liquefied petroleum gas, chloromethane, etc. High temperature type generally transports media with a maximum temperature of 350 degree celsius, a maximum flow rate of 300m3/h, and a maximum head of 115m, suitable for high-temperature liquids such as oil and hot water. High melting point pumps and motors with jackets can significantly improve the heat resistance of the motor. Suitable for high melting point liquids, with a maximum temperature of 250 degree celsius. The jacket can be filled with steam or liquid at a certain temperature to prevent crystallization of high melting point liquids. The casing of a high-pressure shielded pump is a high-pressure vessel, which enables multi-stage pipeline pumps to withstand high system pressures. To support the shielding sleeve under high internal pressure, the stator coil can be used to withstand pressure. When the self-priming suction tube is not filled with liquid, the pump discharges the liquid through automatic pumping, which is suitable for extracting liquid from underground containers. The multi-stage type is equipped with multiple impellers, suitable for high head fluid transportation, with a maximum head of up to 400m. Mud type is suitable for transporting liquids mixed with large amounts of mud.

Specification

canned motor pump

electric pump

chemical pump

transfer pump

industrial pump

no leakage pump

Samples information

Port of shipping

China

Shanghai Port

About the supplier

Visit supplier pageContact supplier

More products from the supplier

Similar product

Sewage Pumps

Our range of sewage dewatering pumps is capable of ha...

Cosmos Pumps Priv...

IH Stainless steel...

Stainless steel chemical pump IH chemical pump mee...

Kenshine Pump Mfg...

LW Vertical sewage...

Outdoor vertical sewage pump. The pump is a vertic...

Kenshine Pump Mfg...

IHF horizontal ant...

Chemical centrifugal pump for acids unloading IHF ...

Kenshine Pump Mfg...

DBY electric diaph...

Electric double diaphragm transfer pump. The motor...

Kenshine Pump Mfg...

CQ-F Polypropylene...

CQF engineering plastic magnetic pump is the applicat...

Kenshine Pump Mfg...

UHMWPE, PVDF, F46 ...

Engineering plastic centrifugal pump with open impell...

Kenshine Pump Mfg...

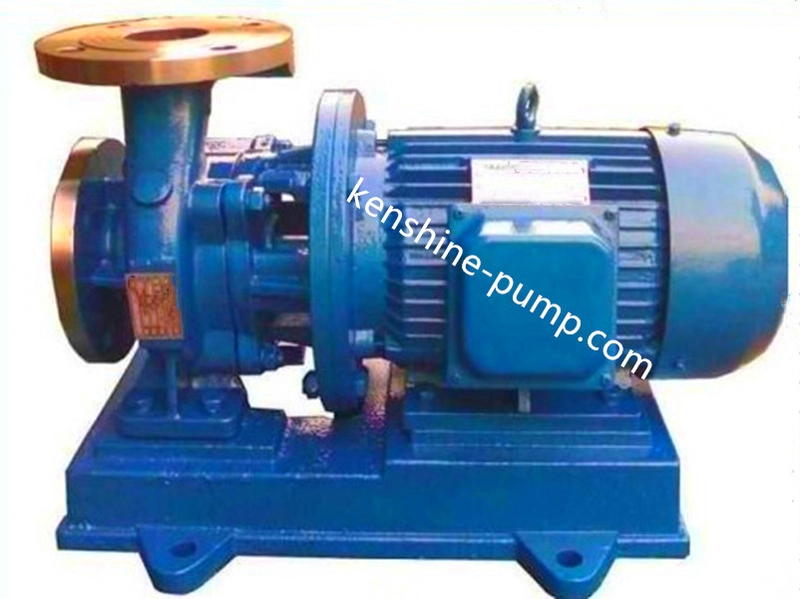

ISW horizontal cen...

Horizontal monoblock centrifugal pump. The pump can b...

Kenshine Pump Mfg...

ISG Vertical in-li...

Single stage single suction centrifugal vertical pump...

Kenshine Pump Mfg...

FG Single screw pu...

Sanitary screw pump The flow parts of Sanitary scr...

Kenshine Pump Mfg...