3 Axis Vertical Machining Center

Product price

Price upon request

Payment and shipping information

3 Axis Vertical Machining Center

Dalian Polyfull Intelligence Technology Co.,Ltd.

Product details

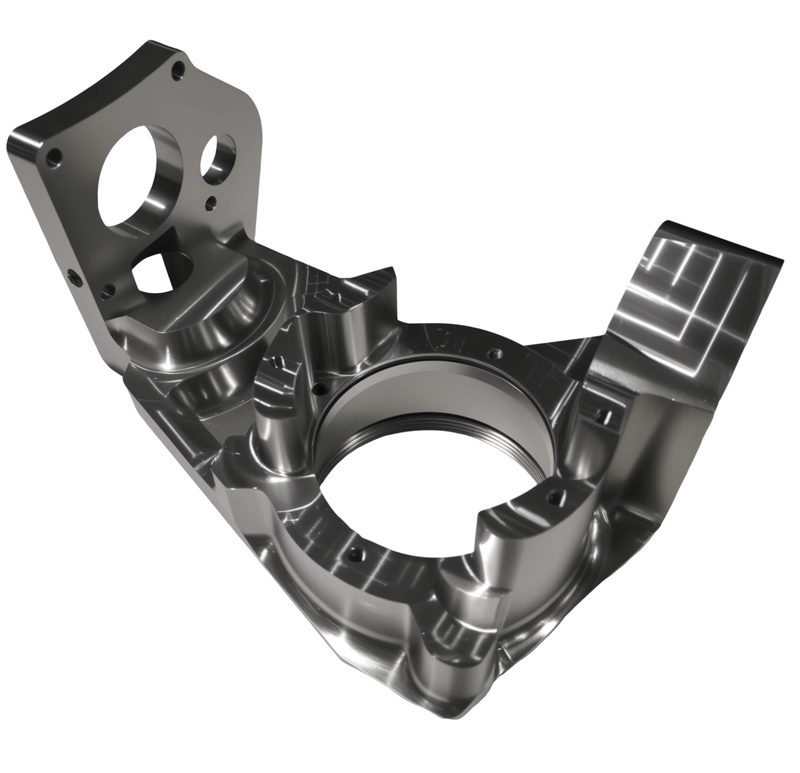

High-Rigidity 3 Axis Vertical Machining Center for Precision Industrial Applications. Our 3 Axis Vertical Machining Center is a high-performance solution engineered for precision, speed, and reliability across a wide range of industrial machining needs. Designed with a robust structure and advanced components, this 3-axis vertical CNC machine ensures consistent accuracy in small to medium-batch production environments. Whether you are in automotive, aerospace, electronics, or mold manufacturing, this CNC center offers optimized machining efficiency with high structural rigidity and ease of operation. Key Features. 1. This CNC vertical milling center adopts a high-rigidity architecture, built to maintain dimensional stability during high-speed cutting operations. The XY axes utilize Taiwan HIWIN heavy-duty roller linear guideways, known for their low friction, fast response, and high accuracy. In the Z-axis, a robust hard rail structure provides added stiffness, ideal for vertical loads and deep-cutting strength. 2. Spindle Unclamping Mechanism: The spindle is equipped with a turbocharged cylinder from a reputable Taiwanese supplier, ensuring safe and reliable automatic pneumatic tool release. This feature significantly reduces tool change time and boosts productivity. 3. High-Precision Ball Screws: For all three axes, we use custom-made C3-level ball screws from Taiwan's HIWIN or PMI, delivering superior transmission efficiency and precision. The feed mechanism is enhanced by professional-grade NSK P4 bearings, maintaining long-term stability and wear resistance under demanding conditions. 4. Thermal Stability & Protection: The machine's electrical box includes a cooling system, and its three-dimensional full-protection cover minimizes thermal distortion while maximizing operator safety. This configuration makes the machine highly suitable as a CNC vertical mill with rigid structure capable of handling both intricate detailing and bulk metal removal. Standard Configuration. 1. Taiwan Jianchun spindle, BT40/8000rpm. 2. C3-level Taiwan PMI/HIWIN ball screws (X/Y: 4016, Z: 4016). 3. Taiwan Shangyin roller linear guide (specially re-cut). 4. Four hard rails in the Y-direction with wear-resistant plastic sliding surface. 5. Japan NSK P4 precision bearings. 6. Taiwan AIMACH 24-tool automatic tool magazine. 7. Electrical box with active cooling system. 8. Automatic lubrication system and cooling water pump. 9. XYZ axis fully enclosed protective shield. 10. Integrated water-air cooling system for the workpiece. 11. Handheld air gun & water gun. 12. Three-color warning indicator, foundation bolts, and machine base pads. This comprehensive feature set supports its function as an industrial 3-axis CNC mill, enabling high-efficiency metal part processing with minimal downtime.

About the supplier

Visit supplier pageContact supplier

More products from the supplier

Similar product

Gantry CNC Machini...

Our products are manufactured using large gantry CNC ...

Wuxi Yanxiang Tec...

Linear Rail CNC M...

High-Precision Linear Rail CNC Machine for Modern Man...

Dalian Polyfull I...

3 Axis Vertical Ma...

High-Rigidity 3 Axis Vertical Machining Center for Pr...

Dalian Polyfull I...

Fixed-column type...

Fixed-column type vertical machining center machine t...

Dalian Polyfull I...

High Rigidity 2-Wi...

1. The High Rigidity 2-Wire 1-Hard Machining Center i...

Dalian Polyfull I...

High-speed And Hig...

The High-speed and High-precision Parts Machining Cen...

Dalian Polyfull I...

High-speed Drillin...

1. High-speed drilling and tapping machine, is a kind...

Dalian Polyfull I...

Highly rigid 3-axi...

Highly rigid 3-axis vertical machining center is a ki...

Dalian Polyfull I...

High Rigidity Hard...

1. The High Rigidity Hard Rail Gantry Machining Cente...

Dalian Polyfull I...

CNC Hydraulic Bend...

CNC hydraulic bending machine. We are a professional ...

Saint Fighter (Sh...