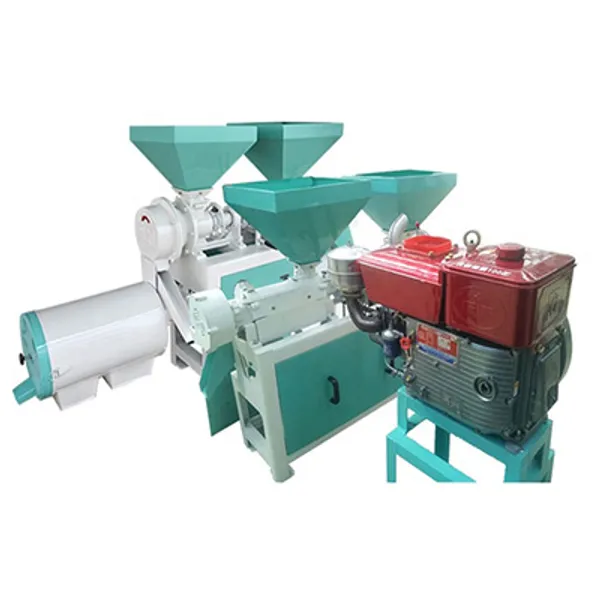

TQNF-15T Combined Corn Grits And Flour Unit

TQNF-15T Combined Corn Grits And Flour Unit

Lushan Win Tone Engineering Technology., Ltd

Product price

Price upon request

Product details

Application:Corn cleaning, corn peeling, corn grits, corn flour Capacity:15Ton/day DESCRIPTION TQNF-15T multifunctional corn grits and corn flour whole set of equipment adopts multi-module and split type of streamlined design. The machining process is controlled by complete automation and can realize continuous operation in 24 hours. It is suitable for various kinds of grains processing, such as corn processing, soybean processing, mung bean processing, wheat processing, millet processing and sorghum processing. WORK PROCESS The unprocessed grains are put into the feeding hopper of the single mechanical elevator and is conveyed to TQS-50 cleaning and stone removing combination machine by TTG19/8D single mechanical elevator. Then it can remove the big and small impurities and stones with similar gravity with grains from the raw material. The net grains flow into the mechanical elevator hopper of NFZ-280G peeling and polishing combination machine. Then it is conveyed to NFZ-280G peeling and polishing combination machine by the combination elevator for peeling and polishing. After peeling and polishing, the grain kernels flow into the elevator hopper of YMSF-404 four-size corn grits machine. And then they are conveyed to YMSF-404 four-size corn grits machine by the conveyor for milling. After milling, the corn grits and flour is screened by the cylinder classifying screen and the big, medium and small grits and flour from the screen can be packaged. The exhaust fan aspirates the corn bran into the centrifugal spiral dust remover for corn bran collection. FEATURE Automated working process Streamlined modular design adopts grain cleaning, two sections of peeling, one section of polishing. The whole process is completely automated. Save processing cost The whole processing set just needs one worker for electronic control and one worker for packaging. This can save lots of labor charge. High efficiency It has small power, high efficiency, easy operation and maintenance.It adopts modular design and can process different grains according to requirements. Dry method peeling It adopts dry method peeling, and doesn’t need water in processing. Compared with wet method, it is more sanitary. TECHNICAL INDEX Model Capacity(t/h) Power(kw) Rated voltage(v) Spindle speed(r/min) Weight(kg) Dimension(mm) TQNF-15T 0.8 42.2 380 1042 3220 6460×1060×3400

Payment and shipping information

About the supplier

Visit supplier pageContact supplier

Win Tone

Office manager

More products from the supplier

Similar product

NF Double Cereals...

We have different types of roller mills, which consis...

Lushan Win Tone E...

YTZSF28-5B Upgrade...

YTZSF28-5B maize grits and flour milling machine is i...

Lushan Win Tone E...

HTZ-3B Corn Grits ...

DESCRIPTION HTZ-3B Corn Grits and Flour Milling Mac...

Lushan Win Tone E...

TQNF-15T Combined...

Application:Corn cleaning, corn peeling, corn grits, ...

Lushan Win Tone E...

MTPS Peeling Machi...

DESCRIPTION Dehulling grain legumes by traditional ...

Lushan Win Tone E...

MTPS Lentil Peelin...

DESCRIPTION Lentil, also Massor Pulses, can be also ...

Lushan Win Tone E...

NZJ-15C Combined M...

Application:Millet cleaning, removing stones and impu...

Lushan Win Tone E...

HTG Sorghum Peelin...

HTG Sorghum Peeling Machine Application:The mach...

Lushan Win Tone E...

electric modular t...

Introducing an electric modular three-deck oven, a ke...

ALTUNTOP ISI VE M...

commercial rotatio...

Introducing our industrial-grade Commercial Rotation ...

ALTUNTOP ISI VE M...