Z aib D illawer

Sales manager

Percussion hammers, in a general sense, are tools or devices designed to deliver repeated blows or impacts. Here's a broad outline of the manufacturing process for a typical percussion hammer: Design and Engineering: Define the specifications and requirements of the percussion hammer. Create detailed engineering drawings and plans for manufacturing. Material Selection: Choose appropriate materials for the hammer head, handle, and any other components. Consider factors such as strength, durability, and weight. Material Preparation: Prepare raw materials for processing. Cut and shape materials according to design specifications. Forging or Casting: Forging involves shaping the metal through controlled heating and hammering. Casting involves pouring molten metal into molds to achieve the desired shape. Finishing: Apply coatings or finishes to protect against corrosion or improve aesthetics. Perform any additional surface treatments as needed. Quality Control: Conduct rigorous quality control checks to ensure the hammer meets specified standards. Inspect dimensions, material quality, and overall functionality.

Port of shipping

Pakistan

Karachi

Sales manager

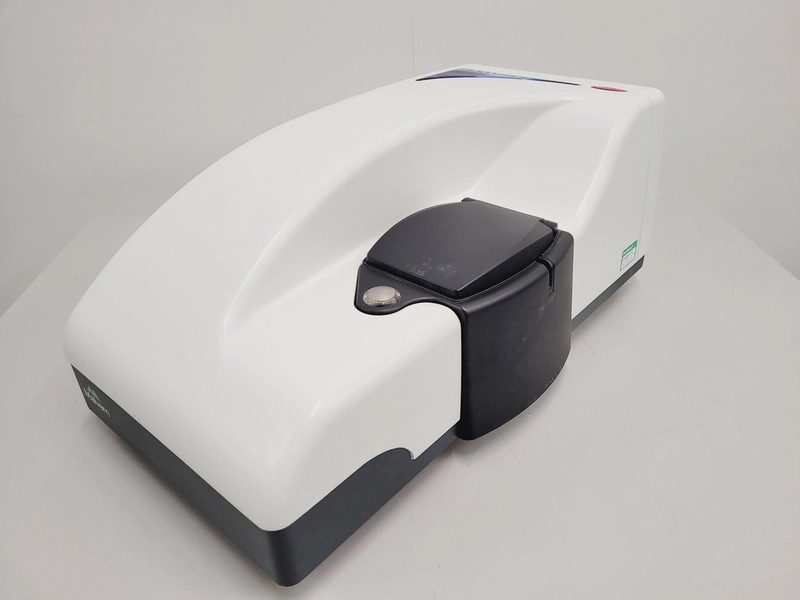

The Mettler Toledo DSC 1 Differential Scanning Calori...

Gridatama Equipme...

The Thermo Scientific Cellomics ArrayScan VTI HCS Rea...

Gridatama Equipme...

Malvern Instruments Zetasizer Nano-ZS ZEN3600 Particl...

Gridatama Equipme...

High Quality Stainless Steel Chevalier Jackson Trache...

Even Instruments ...

Electrosurgical Ophthalmic Bipolar Coaptation Forceps...

Even Instruments ...

Premium Quality Microsurgery Instrument Micro Scissor...

Even Instruments ...

This German sutureless vasectomy meatotomy urology su...

Even Instruments ...

This high-quality stainless steel Harbert mallet with...

Even Instruments ...

This waterproof medical therapy self-adhesive bandage...

Multiglobeapp Tra...

We provide two types of nebulizers, both CE/FDA certi...

henan tianzhan me...