Degassing Machine Rotor & Shaft

Product price

30 - 90 USD per Piece

Payment and shipping information

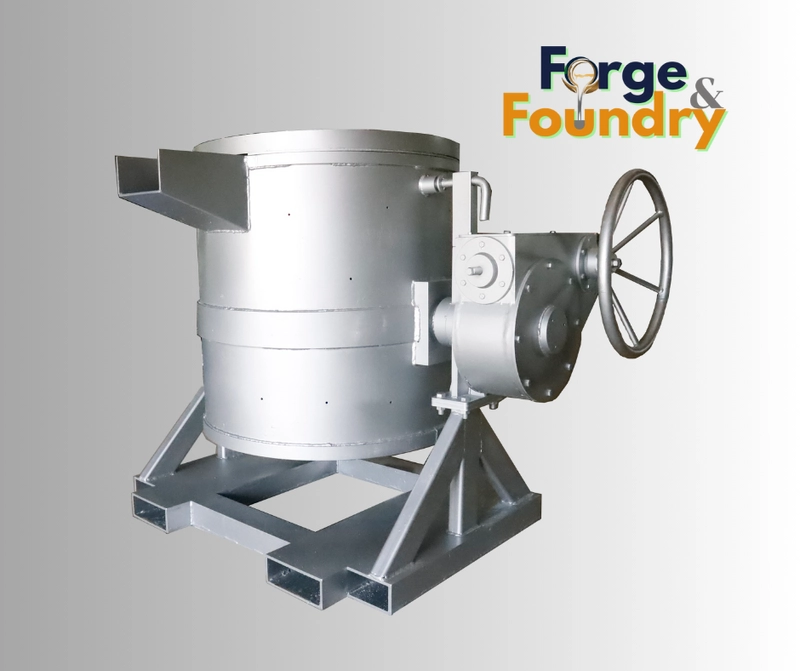

Degassing Machine Rotor & Shaft

Forge & Foundry

Product details

Degassing machine rotors and shafts are critical components in the molten metal treatment process, particularly in foundries handling non-ferrous metals like aluminum. Their primary function is to efficiently remove dissolved hydrogen gas and non-metallic inclusions, which can lead to significant defects such as porosity in the final casting. The rotor, typically positioned at the end of the shaft, spins at high speeds within the molten metal, creating a vortex and dispersing an inert purging gas (like argon or nitrogen) into fine, uniformly distributed bubbles. This maximizes the contact surface area between the gas bubbles and the molten metal, facilitating the effective flotation and removal of impurities and dissolved gases, ultimately leading to a cleaner, higher-quality melt. The design and material selection for these components are paramount to their performance and longevity in the harsh, high-temperature environment of molten metal. Rotors and shafts are often manufactured from advanced materials such as high-purity graphite or specialized ceramics, which offer exceptional resistance to thermal shock, oxidation, and erosion. Their robust construction ensures consistent and reliable operation, minimizing the need for frequent replacements and reducing costly downtime in production. By contributing to superior metal purity and extending the lifespan of critical equipment, high-quality degassing machine rotors and shafts are indispensable for achieving efficient, cost-effective, and high-quality casting operations.

Port of shipping

India

Nhava Sheva Port

About the supplier

Visit supplier pageContact supplier

More products from the supplier

Similar product

Cobalt Alloy 6 Ste...

Cobalt Alloy 6 also known as Stellite 6, CoCr6, Cobal...

Sunrise Steels

Zirconium Bent Pip...

Applications of zirconium bent pipes. Chemical indus...

Baoji Dongying sp...

Zirconium Forgings...

Zirconium forgings are mainly used in high-end fields...

Baoji Dongying sp...

Zirconium screws H...

Chemical industry: Can be used in chemical reaction v...

Baoji Dongying sp...

Heavy Duty Girth G...

A girth gear is a large rotating ring gear that encir...

LUOYANG CITICIC I...

K-Mould For Alumin...

Forge & Foundry offers high-quality K-Moulds specific...

Forge & Foundry

Degassing Machine ...

Degassing machine rotors and shafts are critical comp...

Forge & Foundry

Die Casting Spray ...

Forge & Foundry stands as a leading manufacturer and ...

Forge & Foundry

Cast grinding ball...

Product name: Casting grinding ball Size: Diameter 12...

Fuxin mining Bure...

Laser Ceramic Plun...

Forge & Foundry's Laser Ceramic Plunger Tip for HPDC ...

Forge & Foundry